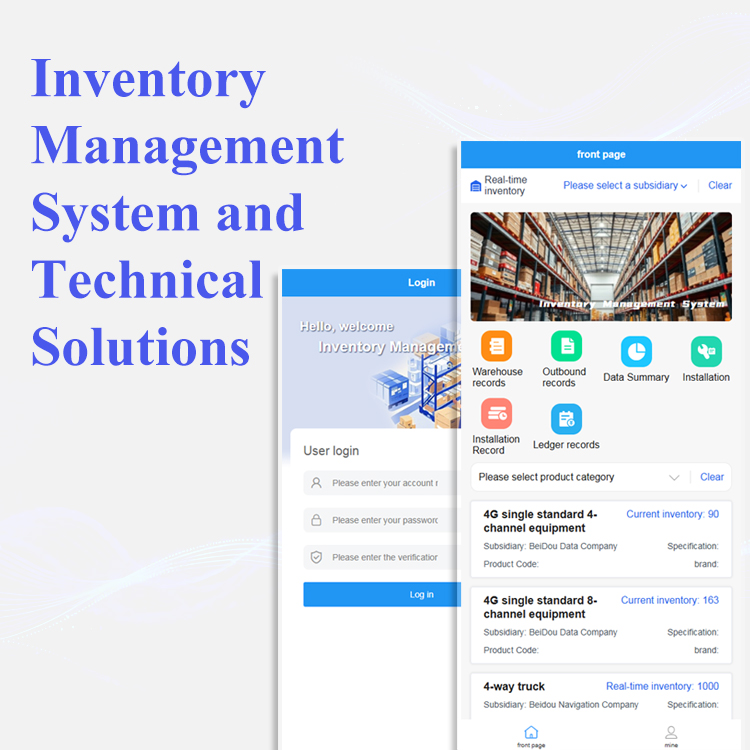

System Introduction

The intelligent warehouse management system serves as a core tool for enterprises to achieve refined management of inventory and assets. The system deeply integrates warehouse, material, supplier, and inventory inbound and outbound operations as well as installation management. It supports real-time collaboration and data-driven operations across multiple warehouses, encompassing the entire supply chain process from procurement, internal circulation, to sales delivery.

This system precisely serves enterprises in manufacturing, trade and commerce, chain retail, and project services, effectively addressing core pain points such as inaccurate inventory, lack of traceability, and low efficiency. It helps enterprises achieve inventory visualization, standardized operations, and digital management.

We offer two delivery methods: SaaS cloud subscription and on-premises deployment, balancing flexibility and security while supporting customized development tailored to enterprise needs. Our delivery content not only includes system deployment, data migration, and training support, but also focuses on configuration services that match business processes, ensuring that the system is truly usable and well-managed, providing reliable support for enterprises to reduce costs and increase efficiency.

Service process

Requirements Gathering and Consolidation

Requirements Analysis and Confirmation

UI Design and Confirmation

Architecture Design

Front-end and Back-end Development

Software Testing

Software Deployment and Launch

List of features for the base edition:

| Presentation end | functional module |

|---|---|

| Central computer end | Subsidiary management |

| Login | |

| user management | |

| store management | |

| Material classification | |

| Material information management | |

| tabulate statistics | |

| Mobile Center | Real-time inventory |

| Inventory records | |

| Records of deliveries | |

| Data collection and statistics | |

| Warehouse management mobile terminal | Real-time inventory |

| Inventory management | |

| Outbound management | |

| More features support customized development, contact customer service for better service | |

Application Scenarios

Production and spare parts management:

Scenario: The raw materials, semi-finished products, finished goods, and a large quantity of equipment maintenance spare parts purchased by the factory are scattered across various workshops and warehouses. The requisition process is chaotic, items are hard to locate, and inventory backlog is severe.

System solution: Through product management and warehouse management, achieve unified coding of materials. Implement outbound and inbound management + audit management, standardize the material requisition process, and eliminate random requisition. Manage serial numbers to accurately track the core components of key equipment.

Distribution and sales management:

Scenario: Brand owners or large wholesalers often establish central warehouses and multiple distribution warehouses. Due to the wide variety of products and complex circulation, issues such as cross-regional channeling and lagging inventory data are prevalent, leading to poor allocation, inaccurate sales decisions, and difficulty in achieving refined operations.

System solution: Multi-warehouse management enables headquarters to view real-time inventory across all sub-warehouses. Strict outbound auditing can be linked to customer information, controlling grey market activities from the source. Clear inbound and outbound statistics display sales and return data from various channels.

Project-based sales and implementation:

Scenario: Sales of large-scale equipment, specialized instruments, or integrated projects involving software and hardware. Equipment needs to be recorded with a serial number before leaving the factory, undergoes debugging (installation management) before shipment, requires acceptance management upon arrival at the customer's site, and relies on clear ledgers for asset ownership and after-sales service.

System solution: The system integrates sales orders, equipment serial numbers, outbound deliveries, installation feedback, and acceptance forms into a comprehensive project archive, creating an equipment ledger that perfectly supports full-cycle project management and after-sales traceability.

Asset-intensive enterprises:

Scenario: Schools, hospitals, hotels, large enterprises and institutions, possessing a large amount of fixed assets (computers, air conditioners, office equipment, etc.) and consumables inventory. Asset inventory is difficult, borrowing and return are unclear, and the idle rate is high.

System solution: Manage fixed assets as "special inventory" and identify them through serial numbers or labels. Collecting or borrowing is considered as "outbound", and returning is "inbound". The ledger reflects the asset status, location, and user in real time, transforming extensive management into refined management.

Applicable Enterprises

Enterprises centered around hardware products, encompassing processes such as warehousing, supply, installation, and acceptance (particularly equipment manufacturers and project-oriented enterprises)

Manufacturing enterprises: Applicable to discrete manufacturing industries such as equipment assembly, electronic and electrical, and furniture customization, especially suitable for factories with complex bill of materials structures and high spare parts management requirements.

Dealers of instruments, meters, and industrial equipment: catering to the circulation sector of high-priced and highly compliant instruments, meters, and industrial equipment, we offer comprehensive process control functions such as serial number management, installation acceptance, and asset ledger management, meeting the needs for precise traceability and after-sales management.

Brand consumer goods operator: specializing in digital products, home appliances, beverages, etc., with needs for anti-channeling and traceability.

Commercial and trade wholesale enterprises: For wholesalers with large inventory volumes, multiple warehouse operations, or plans for expansion, it supports unified management across multiple warehouses and dynamic synchronization of inventory, enhancing order fulfillment efficiency and inventory turnover levels.

Project-based sales company: Engaged in system integration, environmental protection engineering, smart home, and other project-driven enterprises, providing project material requisition, asset tracking, and cost aggregation functions to achieve material control throughout the entire project process.

Chain retail enterprises: Serving retail brands with central warehouses and multiple stores, supporting unified warehouse management and distribution, intelligent replenishment, and inventory visualization, enhancing supply chain response speed and store stock availability.

Delivery of the content

1.Source code of the program

2.Data structure design document

3.System operating instructions

after-sale service

1.Free system after-sales service for one year, system error and BUG repair

2.remote assistance

3.on-line training

4.Regular customer return visits

Our comprehensive solutions will help you overcome challenges, unleash growth, and achieve your goals. Contact our experts to discuss your needs and get tailored solutions and quotes.